- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

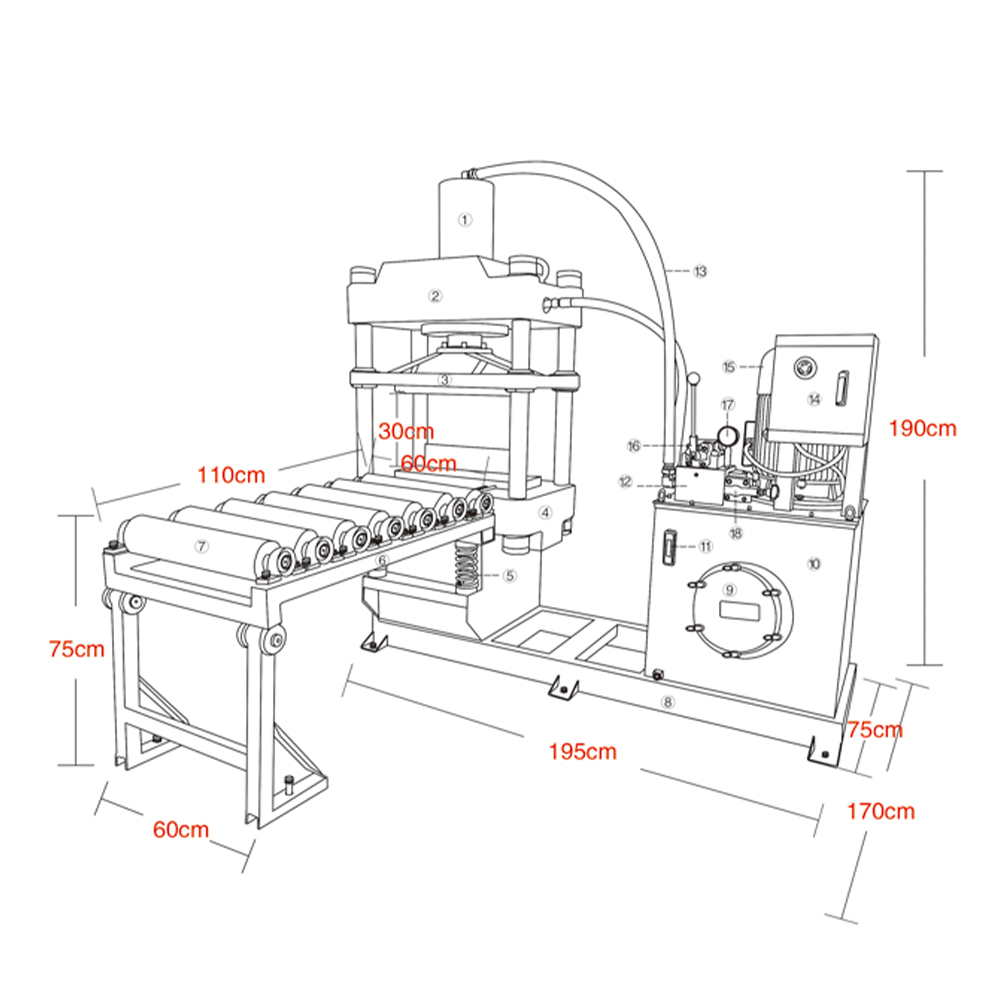

Hydraulic Stone Splitting Machine – The Perfect Solution for Saw-Cut Face Cutting and Stone Stamping.

Our hydraulic stone splitting machine is ideal for saw-cut face cutting and stone stamping, as it features a robust and durable construction that can handle even the toughest materials. With a powerful hydraulic system that delivers high pressure for precision splits, our machine allows you to work faster and more efficiently, saving you both time and money.

Whether you are working with natural stone, granite, marble, or other materials, our hydraulic stone splitting machine is built to handle it all. Equipped with precision blades that can be adjusted to different cutting depths and widths.

| Product Parameters | ||

| Type | Unit | RSS-150 |

| Overall Dimension | cm | 195x170x190 |

| Weight | T | 1.5 |

| Power | kw | 11 |

| Voltage | V | 380 |

| Frequency | HZ | 50 |

| Pressure | T | 150 |

| Flow Rate | L/M | 32 |

| Hydraulic Oil Grade | 46# | |

| Blade Feeding Speed | cm/s | 5 |

| Max.Working Height | cm | 30 |

| Max.Working Width | cm | 60 |

| Output/Hour | m2 | 20 |

| Oil Tank Capacity | 135L/110KG | |

| Packing Size | cm | 205x85x200 |

| Weight | T | 1.7 |

Q: What is a stone splitting machine?

A: A stone splitting machine is a mechanical device used in the construction industry to break large blocks of stone or rock into smaller pieces that can be used for building or landscaping purposes.

Q: How does a stone splitting machine work?

A: Different types of stone splitting machines use different mechanisms, but most of them rely on hydraulic or pneumatic pressure to exert force on the stone block until it cracks along the desired line. Some machines are operated manually or with electric motors.

Q: What are the benefits of using a stone splitting machine?

A: Stone splitting machines offer several advantages over traditional methods of stone cutting, such as speed, precision, and safety. They can reduce the amount of waste generated during the cutting process and enable workers to handle larger and more complex stone pieces that would be difficult or impossible to cut by hand.

Q: What types of stones can be split with a stone splitting machine?

A: Stone splitting machines can be used on a variety of stones, including granite, marble, limestone, sandstone, and quartzite. The suitability of a particular stone for splitting depends on its hardness, toughness, and grain structure.

Q: How do I choose the right stone splitting machine for my needs?

A: When choosing a stone splitting machine, consider factors such as the type and size of stones you need to split, the volume of work you expect to handle, the available power source, and the cost and maintenance requirements of the machine. It's also helpful to read reviews and compare specifications from different manufacturers to find the best fit for your budget and application.

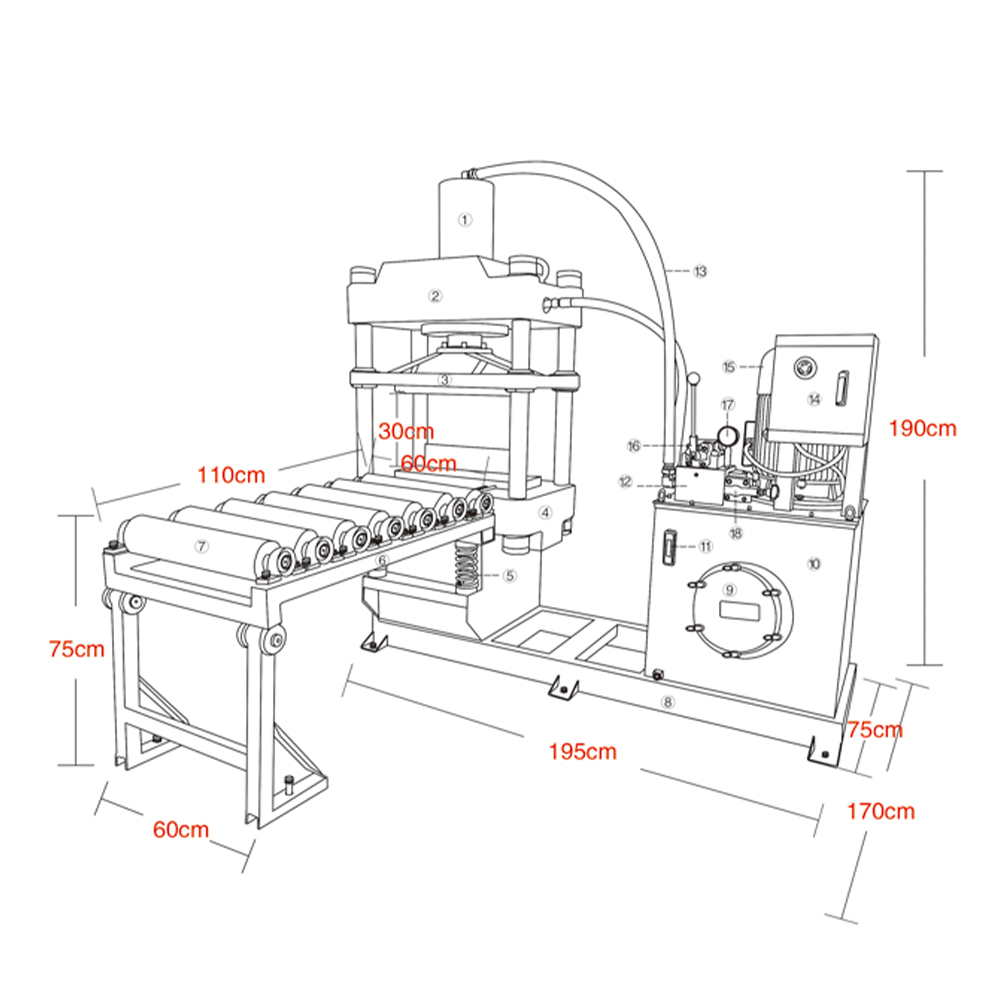

Hydraulic Stone Splitting Machine – The Perfect Solution for Saw-Cut Face Cutting and Stone Stamping.

Our hydraulic stone splitting machine is ideal for saw-cut face cutting and stone stamping, as it features a robust and durable construction that can handle even the toughest materials. With a powerful hydraulic system that delivers high pressure for precision splits, our machine allows you to work faster and more efficiently, saving you both time and money.

Whether you are working with natural stone, granite, marble, or other materials, our hydraulic stone splitting machine is built to handle it all. Equipped with precision blades that can be adjusted to different cutting depths and widths.

| Product Parameters | ||

| Type | Unit | RSS-150 |

| Overall Dimension | cm | 195x170x190 |

| Weight | T | 1.5 |

| Power | kw | 11 |

| Voltage | V | 380 |

| Frequency | HZ | 50 |

| Pressure | T | 150 |

| Flow Rate | L/M | 32 |

| Hydraulic Oil Grade | 46# | |

| Blade Feeding Speed | cm/s | 5 |

| Max.Working Height | cm | 30 |

| Max.Working Width | cm | 60 |

| Output/Hour | m2 | 20 |

| Oil Tank Capacity | 135L/110KG | |

| Packing Size | cm | 205x85x200 |

| Weight | T | 1.7 |

Q: What is a stone splitting machine?

A: A stone splitting machine is a mechanical device used in the construction industry to break large blocks of stone or rock into smaller pieces that can be used for building or landscaping purposes.

Q: How does a stone splitting machine work?

A: Different types of stone splitting machines use different mechanisms, but most of them rely on hydraulic or pneumatic pressure to exert force on the stone block until it cracks along the desired line. Some machines are operated manually or with electric motors.

Q: What are the benefits of using a stone splitting machine?

A: Stone splitting machines offer several advantages over traditional methods of stone cutting, such as speed, precision, and safety. They can reduce the amount of waste generated during the cutting process and enable workers to handle larger and more complex stone pieces that would be difficult or impossible to cut by hand.

Q: What types of stones can be split with a stone splitting machine?

A: Stone splitting machines can be used on a variety of stones, including granite, marble, limestone, sandstone, and quartzite. The suitability of a particular stone for splitting depends on its hardness, toughness, and grain structure.

Q: How do I choose the right stone splitting machine for my needs?

A: When choosing a stone splitting machine, consider factors such as the type and size of stones you need to split, the volume of work you expect to handle, the available power source, and the cost and maintenance requirements of the machine. It's also helpful to read reviews and compare specifications from different manufacturers to find the best fit for your budget and application.